World-class aluminium extrusion profiles designed for precision, durability, and global infrastructure.

Partner with Satya Metal Industries through precision engineering. Let’s build something monumental together.

High-quality billets produced with precise temperature control. Satya Metal’s Hot Top Casting ensures uniform alloy composition, free from defects.

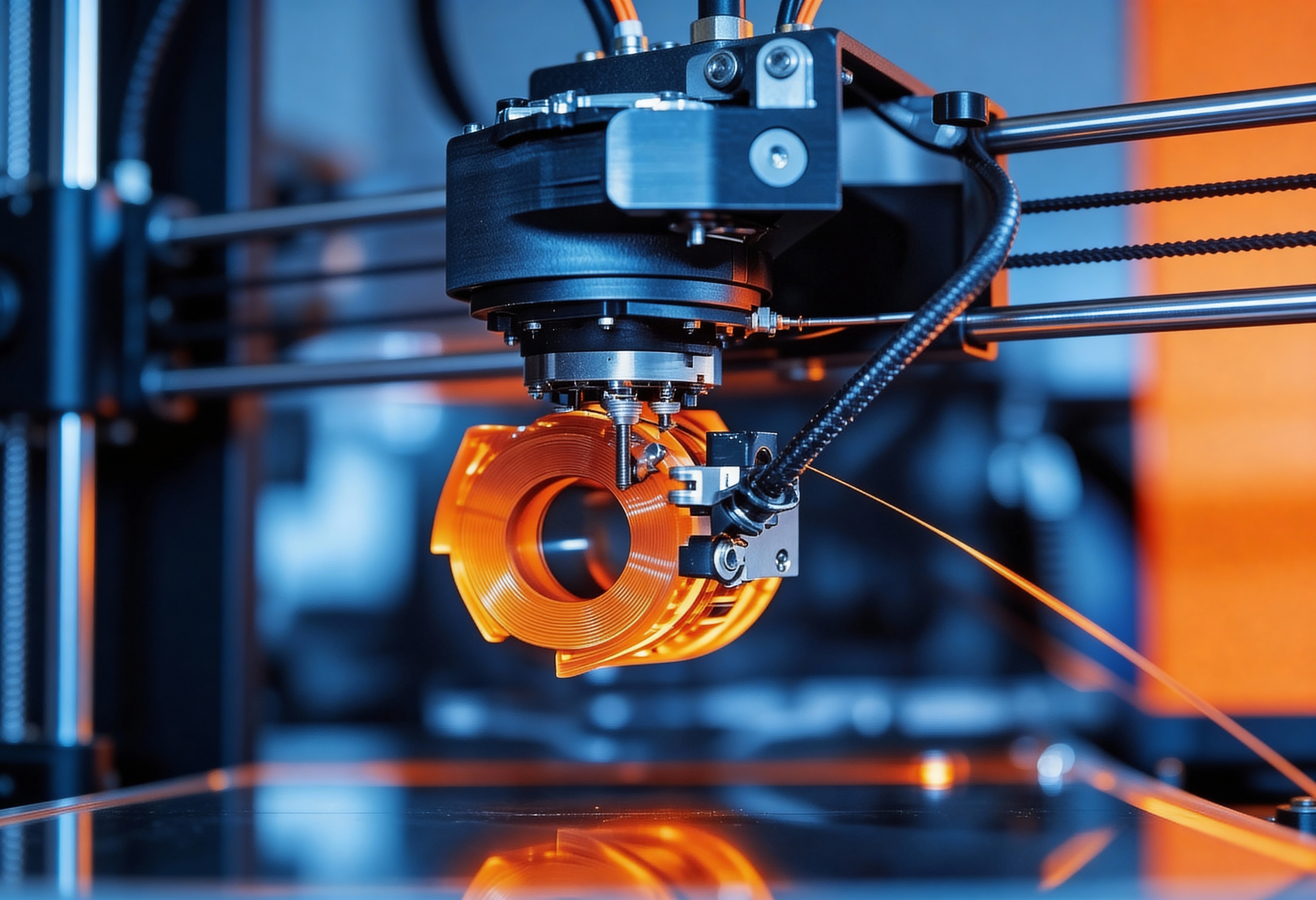

14 high-tonnage PLC-controlled presses deliver complex profiles with exacting precision for industrial and architectural applications.

From anodizing to powder coating, our finishing lines guarantee durability. Eco-friendly processes ensure a lasting, premium surface finish.

Our advanced effluent treatment plants ensure zero liquid discharge, protecting groundwater resources and exceeding global environmental compliance standards.

Harnessing the sun. 30% of our total energy consumption is met through captive solar power plants, significantly reducing our manufacturing carbon footprint.

Aluminium is eternal. Our recycling unit processes scrap with 95% less energy than primary production, driving a circular economy model.

Satya Metal Industries specializes in 6000 series (6063, 6061, 6005) for architectural use and 7000 series (7075) for high-strength industrial applications.

Yes, Satya Metal Industries’ in-house CNC-equipped tool room designs and manufactures custom dies precisely according to your technical drawings.

Satya Metal Industries operates with annual capacity exceeding 50,000 MT, supported by 11 extrusion presses ranging from 650 MT to 4000 MT.

We provide anodizing finishes (matte and gloss), powder coating in RAL shades, and wood grain finishes for durability and premium aesthetics.

Yes, Satya Metal Industries is ISO 9001:2015 certified and exports high-precision aluminium profiles to multiple international markets.