THE POWERHOUSE OF METAL ENGINEERING

Located in Bhiwadi, our plant blends cutting-edge technology, automation, and expertise to deliver precision-engineered aluminium and metal products at scale — fast, reliable, and uncompromising on quality.

Located in Bhiwadi, our plant blends cutting-edge technology, automation, and expertise to deliver precision-engineered aluminium and metal products at scale — fast, reliable, and uncompromising on quality.

Equipped with the world's finest technologies to deliver precision at scale.

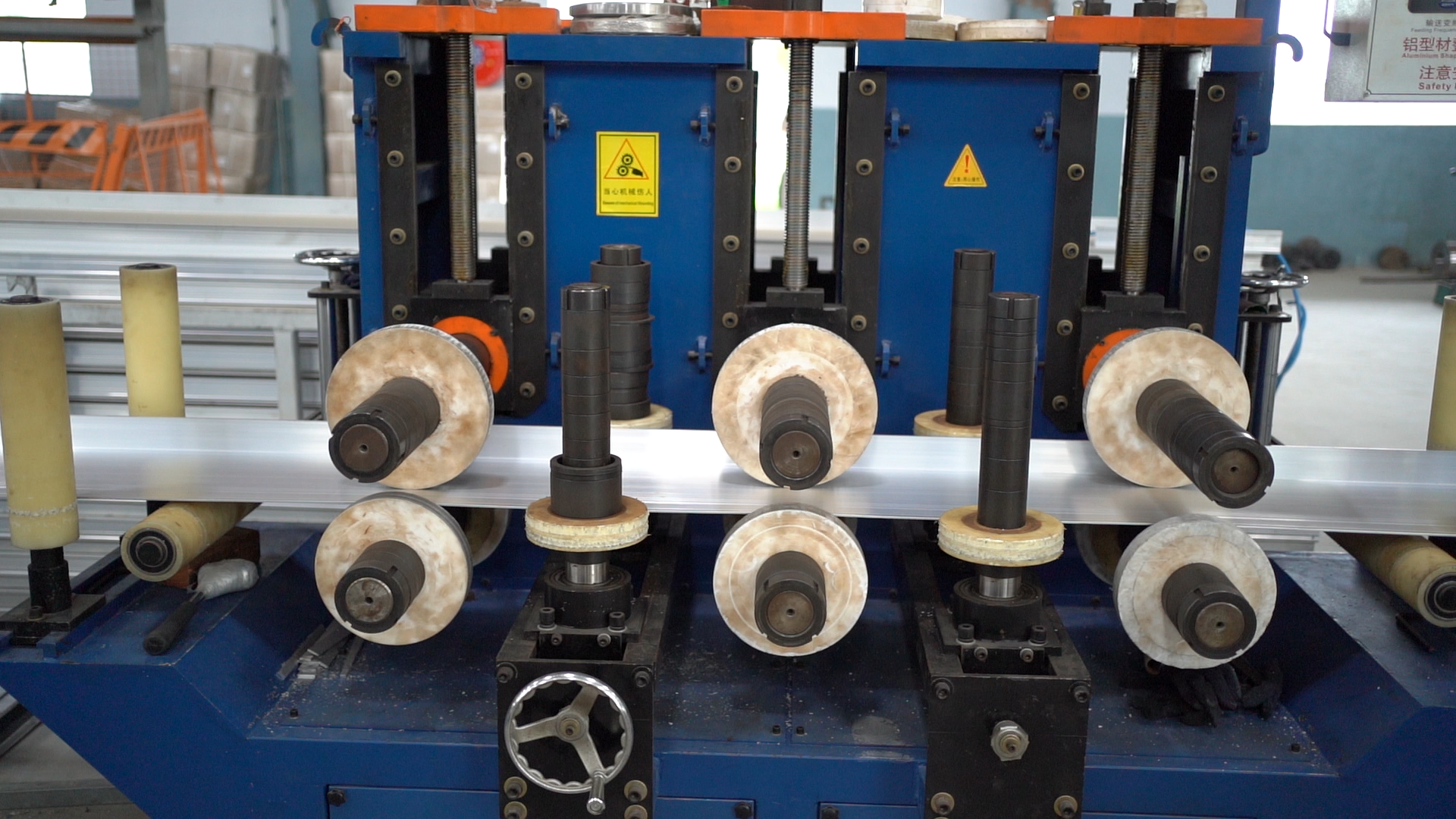

Our Aluminium Extrusion Press-Line features an array of advanced equipment to cater to diverse industry requirements with precision and reliability.

Each press is equipped with all necessary allied equipment to ensure seamless operations and top-notch output. From material handling to final finishing.

Our state-of-the-art heat treatment facility is equipped to meet all your thermal processing needs, ensuring optimal material properties and performance.

Our integrated tool room features over 9000 dies crafted for various profiles. We are at the forefront of delivering bespoke solutions that meet exacting specifications.

To meet our making furnace and casting process form the backbone of our aluminium extrusion services, utilizing advanced technology.

We incorporate a sophisticated homogenizing process for aluminum extrusion in our facility, ensuring the highest quality and consistency.

Our in-house draw bench division features a specialized cold working line. This allows us to provide efficient production processes.

At Satya Metal Industries, manufacturing excellence is matched with rigorous verification. Every aluminium profile undergoes thorough testing in our state-of-the-art Quality Assurance Laboratory.

Advanced spectrometers analyze alloy chemical composition with high precision, ensuring compliance with international quality standards.

Universal Testing Machines (UTM) measure tensile and yield strength, as well as elongation, verifying mechanical robustness for industrial applications.

Webster and Rockwell hardness testers ensure that each profile meets structural durability and resistance requirements.

Our dedicated wet analysis lab rigorously checks anodizing and powder coating quality, guaranteeing superior surface finish and longevity.

From premium billets to precision-engineered profiles, every step of our extrusion process is monitored to ensure exceptional quality, consistency, and performance.

Aluminium billets are pre-heated to optimal plasticity for precise extrusion and minimal defects.

Heated billets are pressed through precision-engineered dies to form complex and accurate profiles.

Rapid and controlled cooling locks in dimensions and microstructure, ensuring uniformity across lengths.

Profiles are straightened and internal stresses are relieved to maintain precise geometry and alignment.

Controlled heat treatment enhances strength while surface finishing provides corrosion resistance and visual appeal.

Harness our state-of-the-art infrastructure, advanced machinery, and expert engineering to achieve flawless extrusion solutions tailored to your requirements.

Get in Touch